In recent years, our customers have experienced a quiet but deep transformation. Companies that once produced millions of parts per year now face a clear and increasingly urgent challenge: produce only what’s needed, when it’s needed, without incurring costs from overproduction or unused inventory.

The market has changed. Today, the logic of make-to-order production, batch customization, and—above all—fast response times dominates. Large warehouse stocks, once considered a competitive advantage, have become a problem: they generate costs, tie up capital, and often end up aging on shelves.

The Limit of Traditional Transfer Machines

In this scenario, many companies are reevaluating their machine fleets.

Traditional transfer machines—designed to ensure high productivity on massive, repetitive volumes—can no longer provide the flexibility required. Long setup times, difficulty managing frequent part changes, and the system’s inherent rigidity are making these machines increasingly unsustainable for those handling small or medium batches.

The Forward-Thinking Alternative: the PORTACENTER

It’s precisely in this context that many companies have started seeing the PORTACENTER as a concrete and advantageous solution.

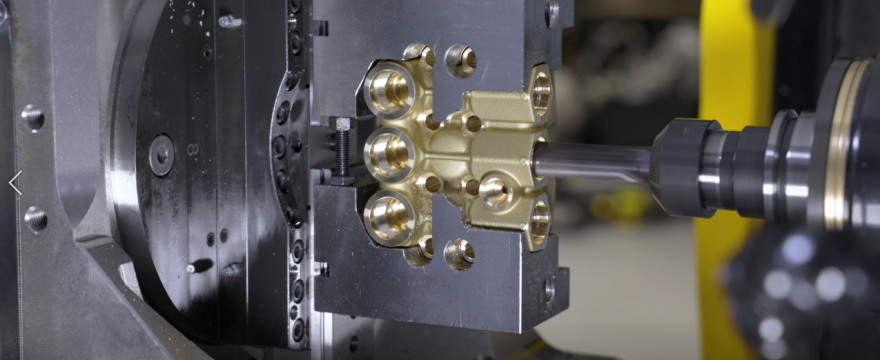

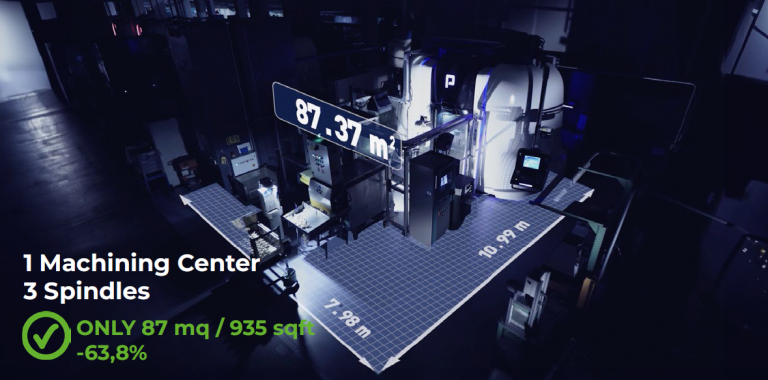

It’s a Machining Center with 3 fully independent spindles, designed to optimize small batch production and drastically reduce setup times.

Its key strength?

Combining the productivity of a transfer machine with the flexibility of a machining center—a rare balance, but essential today.

With the PORTACENTER:

- You reduce time waste: production changeovers take just a few minutes.

- You eliminate warehouse costs: produce only what’s needed.

- You react swiftly to market changes: work on small batches without compromising margins.

- You boost competitiveness: even with increasingly customized customer demands.

Companies That Have Already Made the Leap

Many industry companies have already taken this step. It’s not just an investment in a new machine—it’s a true transformation of the production method. Those who have integrated the PORTACENTER into their operations have managed to:

Switch quickly from machining one component to another.

Eliminate, or nearly eliminate, their finished goods inventory.

Work in a continuous flow based on real orders.

And here’s an interesting fact: companies that adopt the PORTACENTER often go on to purchase a second—or even a third—unit within a few months, after seeing firsthand the positive and tangible impact on productivity, flexibility, and setup times.

Our customer repurchase rate has reached an excellent 68%!

Why? Because the difference compared to previous solutions becomes clear from the very first batches: less waste, faster workflows, and better market responsiveness.

A prime example comes from a company in the industrial valve sector, producing complex parts for both domestic and international markets. Initially constrained by the rigidity of traditional transfer machines and the growing need to manage increasingly variable batch sizes, the company decided to introduce its first PORTACENTER in 2011 to test whether setup times could be drastically reduced while boosting productivity.

The results were so immediate and impressive that, over time, the company went on to purchase its tenth PORTACENTER.

The most appreciated advantage?

The ability to switch from one batch to another within minutes, without losing hours (or even days) on retooling—while maintaining the productivity needed even for medium and small batches.

If you’d like to dive deeper into this case history, you can find the direct evidence of the company’s Production Manager in the book MACHINING CENTERS – How to Cut the Cost per Part and Earn More, written by Maurizio Porta.

Changing Mindset to Change Production

The biggest challenge today is not just technological—it’s cultural.

Because choosing a flexible machine and rethinking production logic also means changing your mindset. And those who’ve had the courage to do so are now working better: more efficiently, with less waste.

Facing challenges like variable batch sizes, long setup times, or growing inventory costs?

👉🏼 Book a free call with one of our Technical Tutors: we’ll analyze your specific case and show you if—and how—the PORTACENTER can concretely improve your production efficiency.