Stop losing orders. Learn how to reduce the cost per part!

In the world of manufacturing, change is never easy. Often, the real obstacle isn’t technical but mental: why should a manufacturing company that has always been profitable question its way of producing?

The answer is as simple as it is urgent: those who don’t evolve, fall behind.

Traditionally, transfer machines offer high productivity for large batches (from hundreds of thousands to millions of pieces), while machining centers stand out for their flexibility but slow down when volumes increase.

To solve this issue, a new category of machine tools was created: the 3-independent-spindle Machining Center, designed to integrate the strengths of both technologies into one single process.

we’ll analyze your specific case and show you how the PORTACENTER can concretely improve your production efficiency.

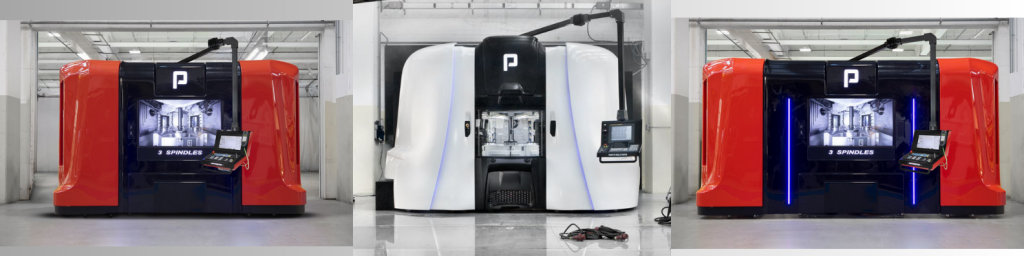

The PORTACENTER represents the new generation of machine tools.

It’s a 3-independent-spindle Machining Center that combines:

The PORTACENTER is designed to be reliable, competitive, and available on short lead times (delivery within 60 to 90 days), thanks to production in series.

It is the ideal solution for batches ranging from 500 to 5,000 pieces but can also handle productions from 100 up to over 10,000 pieces, depending on complexity and repeatability.

Production changeover is streamlined: simply replace the workpiece clamping system.

A real advantage for those who deal with frequent batch changes.

The PORTACENTER is Industry 4.0-ready:

In today’s context, characterized by customization demands, shorter cycles, and cost pressure, relying on a hybrid machine tool like the PORTACENTER can be a real game-changer for manufacturing companies.

It’s not just about buying a machine — it’s about embracing a new production method that combines flexibility, productivity, and cost-per-piece reduction.

👉🏼 Book a free call with one of our Technical Tutors:

we’ll analyze your specific case and show you how the PORTACENTER can concretely improve your production efficiency.