If you are a production manager and use CNC Machining Centers or Twin-Spindle Machines, you will have found yourself at least once in the situation of having to choose a new machine to purchase for your production company (or for the company where you work).

The first thing that comes naturally is certainly to search, among the different brands, for the CNC Machining Center model that best suits your needs, in order to maximize the investment.

After a few weeks or months of research, finally comes the time when you think you have identified the potential supplier (and therefore the ideal machine). And this generates a feeling of pleasure in you, compared to stress felt in the selection phase.

In the vast majority of cases, however, this first phase of research is only the beginning of a long and challenging process in which, from then on, you will have to deal with many other suppliers:

- the company that sells the machine;

- the toolmaker, who will offer you the most suitable tools;

- the fixture builder, with whom you will have to interact to design the best fixture for you;

- the company that supplies the automation system.

So the situation is always the same: you start with the choice of a Machining Center and a single supplier and you find yourself having to make dozens of choices and having to interact with at least 4 or 5 other different companies.

An expensive job, which immeasurably increases the possibility of making the wrong investment, generating a lot of stress and a feeling of frustration in you.

Wouldn’t it be nice to be able to turn to ONLY ONE SUPPLIER AND PERSON, without having to go crazy with a thousand companies?

How would you feel if you could turn to a complete service, a 100% turnkey service, and with one company capable of managing the entire project for you, drastically reducing the probability of failure and significantly increasing your ROI investment?

Well, if your answer is Yes follow me, because there is a solution for you…

Turnkey service on CNC Machining Centers: mistakes to avoid

When you are considering investing in a new machine, there are a number of mistakes you could fall into and which you absolutely must avoid, because they could weaken and make your investments useless.

Here’s what they are…

1 – THINKING ONLY ABOUT THE MACHINE

The first thing to avoid when you are evaluating a new process or CNC Machining Center is to think that the investment is ONLY THE MACHINE.

The machine, even if it is the main element of the investment, actually represents only ONE ELEMENT, and not the whole project.

Thinking only about the machine means believing that the supplier you will turn to is only one, that the problems to be solved will be limited to just the machine; it means overshadowing many other elements that play a crucial role for the investment itself.

2 – CONTACTING THE WRONG MANUFACTURER

It seems trivial and something taken for granted, but often even the most famous manufacturers of Machining Centers and CNC twin-spindle machines are good at the sale of machines, but they make mistakes on everything that concerns your project.

It is therefore important to identify a manufacturer who knows how to follow everything concerning your investment at 360 degrees, who can guide you in all the steps, from the purchase to the testing of the machine.

So, beware of manufacturers who think only of selling their CNC Machining Centers, delegating all the other phases of the project to other companies.

They are to be avoided!

3 – NOT CHECKING IF THERE IS A TECHNICAL TUTOR

A technical tutor is a fundamental figure because he is the real expert in machining operations, with years of experience in the use of Machining Centers, ready to support you throughout the project.

He is very different from the traditional salesman!

The technical tutor is a figure independent from sales activities.

What does it mean?

This means that his real and main objective is not to sell you the machine to get commissions, but to find the winning technical solution to make you decide to purchase the correct Machining Center for your specific production needs.

How can you choose the best machine if you don’t have a technical tutor to support you in the selection process?

How can you make dozens and dozens of choices and solve all the problems that will arise, if at the same time you have to work and manage the internal problems of your company, which necessarily require your attention?

YOU NEED THE SUPPORT OF A TECHNICAL TUTOR…

4 – NOT ASKING FOR A TEST DRIVE SERVICE

Having the mathematical certainty that the numbers stated by a manufacturer (cycle time, cost per part, performance…) are 100% true is an almost impossible and above all very risky operation, because it means relying too much on the manufacturer.

The truth is that studies need a DIRECT PRACTICAL APPLICATION on the machine tool you want to buy, if you want to make the results as concrete and real as possible. Relying solely and exclusively on a study practice, without the support of a practical test, is a very risky choice.

Therefore, when you are selecting the system, it is important to make sure and DEMAND that the manufacturer has a dedicated TEST DRIVE service, to allow you to test the machine before buying it.

This step is essential…

The advantages of a 100% Turnkey Service on CNC Machining Centers

At this point you should understand how important it is to identify a builder who can offer you a 100% TURNKEY SERVICE, without compromise.

A service that allows you to have only the manufacturer as your only contact person.

A service that allows you to have a technical tutor as a point of reference, or a figure who helps you find the best solutions, who knows how to manage all phases of the project and solve problems.

A complete service that allows you to take advantage of the Test Drive, to be sure that the promises made on paper are true, BEFORE signing any contract.

In this way you can finally stay focused on what really matters to you, having only one reference figure (the technical tutor) and avoiding having to interface with thousands of companies and suppliers, which could confuse your ideas, increasing the likelihood of making mistakes.

I know, right now you are most likely thinking:

“Okay, but where do I find this kind of service that doesn’t exist?!”

“Okay, but if most of the builders think only of selling the machine, then I have to deal with all other issues!!”

STOP!

What if I told you that this service really exists?

I can prove it to you…

100% Turnkey Service by Porta Solutions

Porta Solutions is a company with decades of experience in the construction of machine tools for machining operations and in the last 20 years it has specialized in the construction of Machining Centers with 3 independent spindles for metalworking on materials such as steel, brass, cast iron, aluminum.

This type of CNC Machining Centers represents a new category compared to the common one-spindle / twin-spindle Machining Centers and the PORTACENTER is the reference model.

It is a Machining Center with 3 independent spindles that will allow you to produce 3 times faster than a single one-spindle CNC Machining Center.

For years the company has focused on the development of 100% TURNKEY SERVICE, to offer its customers a service that allows them to maximize their investment, with the support of Technical Tutors.

But which are the advantages of 100% Turnkey Service of Porta Solutions?

Here are the advantages:

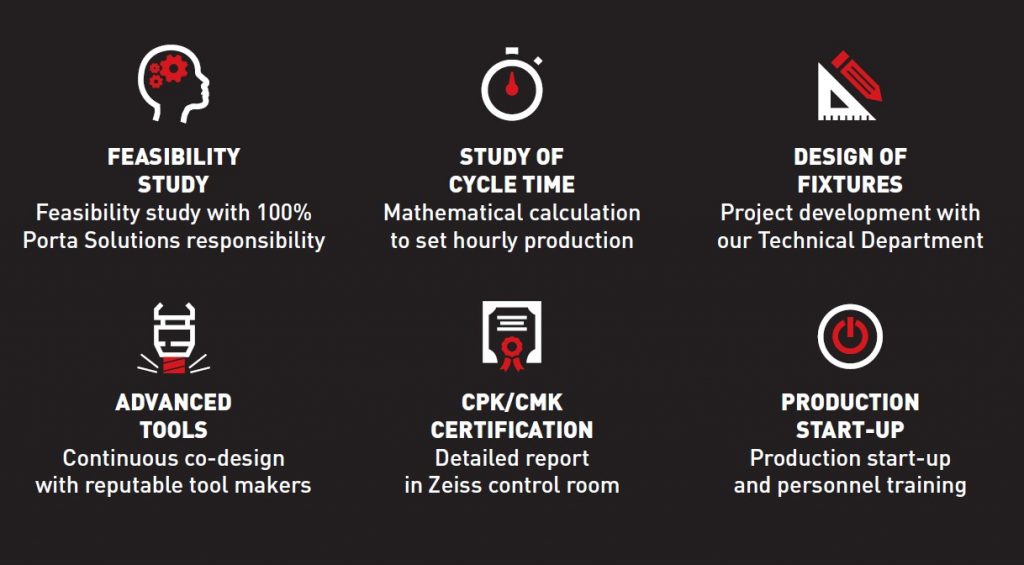

- FEASIBILITY STUDY, complete analysis and study of the whole process, with 100% Porta Solutions responsibility.

- STUDY OF CYCLE TIME, through a mathematical calculation to set the hourly production of your components. This with a “performance” department think tank dedicated to studying how to optimize the cycle time of your components.

- DESIGN OF FIXTURES, complete project development with a dedicated Technical Department within the company.

- ADVANCED TOOLS, continuous co-design with reputable toolmakers with the supervision of your personal Technical Tutor who will guide you in making the best choices, based on the type of material to be machined and the target performance to be achieved.

- CPK/CMK CERTIFICATION, with detailed report produced in the control room with a latest generation Zeiss machine.

- PRODUCTION START-UP, you will be fully followed in the production start-up phase, with additional training of your staff on the working method.

AND ALL OF THIS WITH ONE SINGLE SUPPLIER AS A POINT OF REFERENCE

✅ Without having to interface with a thousand suppliers, each one with their own needs and needs for your attention.

✅ With a dedicated Technical Tutor, with years of experience in the world of machining operations, who will follow you in the project, helping you maximize your investment and avoid dangerous mistakes for the success of the project itself.

✅ With a further report for the analysis of the COST PER PART, through a study based on concepts and methods of Business Economics, they analize all fixed, variable, direct and indirect costs to obtain the “main data” that allows you to obtain an unbelievable competitive advantage over your competitors.

✅ With a ZERO RISK Test Drive service, thanks to which you can try the machine even before signing the contract. A complete test, with fixtures and tools chosen for the components in question. At ZERO RISK, with a guarantee based on 3 levels of security.

100% Turnkey Service of PORTA SOLUTIONS is a guiding star through the realization of a winning project.

But a winning project starts first of all from a winning mentality.

So, now it’s your turn!

Are you a user of Machining Centers in battery and are you evaluating a new machine?

Do you deal with small and medium lots, but you don’t feel sure about making a new investment because the mere thought of having to face a thousand problems blocks you?

Then it’s time to act!

Discover the 100% Turnkey Service of PORTA SOLUTIONS, enter the world of CNC Machining Centers with 3 independent spindles and learn how to REDUCE THE COST PER PART.

Ask for a FREE consultation with one of our TECHNICAL TUTORS.

Phone: +39 030 800673

Email: info@portaproduction.com

To learn more about Competitive Production and PORTA Production Method

CLICK HERE >>> www.machiningcentersbook.com <<<

My book dedicated to users of machine tools who want to make the leap in quality is waiting for you!!!

To your results, Maurizio Porta

Master Trainer PORTA PRODUCTION METHOD